Bulk Carrier in Amsterdam Catches Fire Due to Electrical Short 突发!阿姆斯特丹散货船电线短路,引发火灾!

Bulk Carrier in Amsterdam Catches Fire Due to Electrical Short

突发!阿姆斯特丹散货船电线短路,引发火灾!

On the local date of April 17, 2025, a bulk cargo ship moored at Amsterdam's West Poortweg Quay in the Netherlands caught fire due to an electrical short circuit in the vessel's wiring. After receiving the alarm, the local fire department responded promptly and successfully extinguished the fire. Fortunately, there were no casualties or environmental pollution reported. The extent of damage to the ship remains undisclosed. The fire did not spread to surrounding waters and had no significant impact on the port's operations.

当地时间2025年4月17日,一艘停泊在荷兰阿姆斯特丹西港码头(West Poortweg Quay)的散货船因船内电路系统发生短路,导致火灾。当地消防部门接警后迅速出动,成功扑灭火势。事故未造成人员伤亡或环境污染,具体船损情况尚未公开披露。事故未波及周边水域,也未对码头运营造成显著影响。

Similarly, in the early hours of March 24, 2025, a large inland vessel docked at a Huangpu River wharf suddenly caught fire. Smoke billowed and flames erupted in the living quarters, with the fire spreading rapidly and soon engulfing the entire area. Fortunately, the crew were all on shore at the time, and no casualties were reported. Afterward, through the joint efforts of multiple departments including fire and maritime authorities, the fire was quickly brought under control.

无独有偶,2025年3月24日凌晨,停泊于黄浦江某码头的大型内河船舶突发火情,生活区中浓烟滚滚,明火乍现,且火势迅猛,很快便将整个生活区吞噬。所幸当时该船正在码头进行作业,船员们反应迅速,及时撤离到了岸上,未造成人员伤亡。后经消防、海事等多部门联动,火势被迅速控制。

Subsequent investigations revealed that the crew had used a low-quality, non-branded wireless charging smart power strip to charge a rechargeable lithium battery LED headlamp in the storage room. The fire was caused by a malfunction or short circuit during the charging process.

经过后续深入调查发现,此次事故的根源在于船员违规使用无品牌无线充电插排智能插座,在储藏室内为可充电锂电池LED头灯充电,充电过程中因故障或短路起火。

Image Credit:Internet

Image Credit:Internet

图源网络

Two fires, though geographically distant, reveal common vessel electrical safety risks. The Dutch accident preliminarily indicates system short-circuit due to hull wiring aging or insufficient maintenance. The Shanghai case centers on human-induced risks—crew using low-quality charging devices for lithium-battery headlamps, exposing the psychology of violating electricity - use rules. Experts note that ships, as enclosed and complex spaces, subject electrical systems to humid and vibrating conditions. Without regular inspection or compliant equipment, issues like insulation damage and line overloading can easily cause short-circuits.

两起事件虽相隔万里,却暴露出船舶电气安全的共性风险。荷兰事故调查初步指向船体线路老化或维护不足导致的系统短路,而上海案例则聚焦人为操作隐患——船员使用劣质充电设备为锂电池头灯充电,暴露了违规用电的侥幸心理。专家指出,船舶作为封闭复杂空间,电气系统长期面临潮湿、震动等环境压力,若日常巡检缺失或设备不合规,极易因绝缘破损、线路过载等问题引发短路。

The "lucky" outcomes of both accidents are accidental. The Amsterdam bulk cargo ship fire occurred when the vessel was empty in its berth. The Huangpu River inland vessel fire happened during operations when all crew were on-duty for a rapid response. However, if similar fires break out during navigation or at night when no one is on duty, the consequences could be disastrous. In the past five years, over 40% of global vessel fires were due to electrical faults, with short-circuits being the main cause. Though the International Maritime Organization (IMO) has strengthened electrical inspection requirements in the ISM Code, there are still gaps in implementation.

值得关注的是,两起事故的"幸运"结局存在偶然性。荷兰散货船起火时处于泊位空载状态,黄浦江内河船则因作业期间船员全员在岗得以快速响应。然而,若类似火情发生在航行途中或夜间无人值守时,后果恐不堪设想。数据显示,全球近五年船舶火灾事故中,电气故障占比超40%,其中短路问题尤为突出。国际海事组织(IMO)近年虽强化了《国际船舶安全运营和防止污染管理规则》(ISM规则)中的电气检查要求,但基层执行仍存盲区。

Common Risks of Vessel Electrical Fires

船舶电气火灾的共性风险

Two geographically distant vessel fire incidents reveal core electrical system risks. In the past five years globally, over 40% of vessel fires were due to electrical faults, mainly short - circuits, followed by line overloading and poor contact. Vessels' special environments exacerbate these risks:

两起相隔万里的船舶火灾事故揭示了电气系统的核心隐患。数据显示,全球近五年船舶火灾中电气故障占比超过40%,其中短路问题占主导,线路过载和接触不良次之。船舶特殊环境加剧了风险:

- In enclosed spaces with temperature and humidity fluctuations, metal corrosion rates are 3-5 times higher than on land. The environment is damp, accelerating equipment aging and damage. Additionally, vessel electrical systems are complex, making fault - finding difficult.

- Continuous vibration increases the probability of connection piece loosening to 2.3 times that of land-based equipment. During navigation, vessel movement from sea fluctuations increases electrical-ground fault rates.

- Salty fog accelerates insulation material aging and shortens marine cable life. High salt and moisture content in the maritime environment erode electrical equipment, weakening insulation and speeding up aging, which can cause grounding faults.

- 封闭空间内温湿度波动导致金属腐蚀速率较陆地高3-5倍,环境中水分较多,过于潮湿,电气设备元件在受潮后会加快腐蚀,继而出现老化、受损的情况,且船舶电气系统整体结构较为复杂、故障排查难度大;

- 持续震动使连接件松动概率提升至陆用设备的3倍,船舶航行期间,海水波动较大,海面、海底气压差较大,船舶运行状态容易受到影响,无法时刻保持平稳状态,电气设备在船舶左右摇晃、上下摆动时会因振动而位移、碰撞,导致电气接地故障率增加;

- 盐雾环境加速绝缘材料老化,船用电缆寿命普遍缩短。船舶航行环境相对特殊,海面行驶期间,电气设备设施会长期在盐分较高,且水分较大的环境中,高盐分、潮湿环境会使电气设备内部元件受到侵蚀,弱化设备绝缘性,使其老化速度加快,引起接地故障。

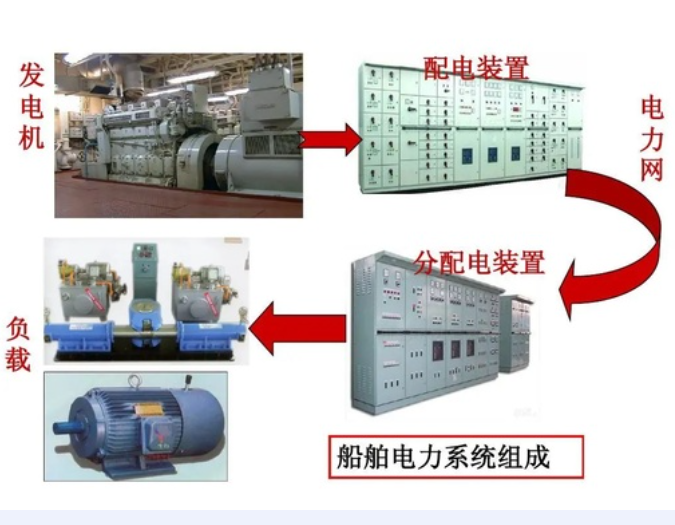

Moreover, vessel electrical systems are intricate. A fault can trigger serious chain reactions, endangering the system's safe operation.

其次,船舶电气系统的组成相对较为繁杂,含有的设备种类较多,一旦发生故障问题,将会造成较为严重的连锁反应,进而影响船舶电气系统的运行安全,造成危险事故的发生。

Image Credit:Internet

Image Credit:Internet

图源网络

IMO Electrical Safety Standards

国际海事组织(IMO)电气安全规范

The IMO has established an electrical safety framework via the SOLAS Convention and ISM Code, with specific requirements:

Explosion - proof requirements for hazardous areas: Vessels carrying dangerous goods must adopt IEC 60092 - 506 standards. Battery rooms must not house arc - producing equipment.

Redundant system design: The main engine room must have two generators. Emergency power should sustain power supply for 36 hours.

Insulation monitoring standards: Shore power systems must undergo quarterly insulation resistance tests, with a threshold of no less than 1 MΩ/kV.

IMO通过《SOLAS公约》和《ISM规则》构建了电气安全框架,具体要求包括:

危险区域防爆要求:载运危险货物的船舶必须采用IEC 60092-506标准,蓄电池室禁止设置可产生电弧的设备

冗余系统设计:主电站需配备双发电机,应急电源应能维持36小时供电

绝缘监测标准:岸电系统需每季度检测绝缘电阻,阈值不低于1MΩ/kV

However, there are three implementation gaps: First, after the 2024 IEC standard update, few fleets have completed equipment upgrades. Second, shore power systems in developing countries have low compliance rates. Third, crew electrical operation training completion rates are low, and re - training cycles often exceed the stipulated period. Case studies show that in Rotterdam Port, the annual electrical inspection pass rate for similar vessels is significantly higher than in Southeast Asian ports.

但执行层面存在三大盲区:①2024年IEC标准更新后,船队完成设备改造占比较低;②发展中国家岸电系统合规率不足;③船员电气操作培训完成率较低,且复训周期普遍超过规定年限。典型案例显示,同类型船舶在鹿特丹港的电气年检通过率显著高于东南亚港口。

Amsterdam Port: A Pioneer in European Green Shipping

阿姆斯特丹港——欧洲绿色航运先锋

The recent Amsterdam incident occurred at the Port of Amsterdam, a trailblazer in European green shipping. The port focuses on shore power system compatibility for vessel circuits. Its strategic plan prioritizes berthing vessels with shore power connection capabilities from 2025 and aims to fully implement the EU AFIR Regulation's mandatory shore power use by 2030.

To ensure ships are more sustainable when berthed, the Port of Amsterdam is to install ship-to-shore power connections by 2025 at the Passenger Terminal Amsterdam (PTA).

此次事故发生在荷兰的阿姆斯特丹港,作为欧洲绿色航运先锋,对船舶电路的核心要求聚焦于岸电系统兼容性。根据港口战略规划,2025年起优先停靠具备岸电连接能力的船舶,2030年全面实现欧盟AFIR法规的强制岸电使用要求。

为确保船舶停靠时更具可持续性,阿姆斯特丹港计划在2025年前在阿姆斯特丹客运码头(PTA)安装船到岸供电设施。

Installing a ship-to-shore power supply at PTA is part of the Port of Amsterdam's "Clean Shipping Vision," a roadmap for more sustainable vessel traffic. Moreover, by 2050, the Port of Amsterdam aims to achieve completely zero - emission vessel traffic. From 2030 onwards, legal requirements will mandate the use of ship - to - shore power by cruise ships.

在PTA安装船到岸供电是“清洁航运愿景”的一部分,这是阿姆斯特丹港制定的路线图,旨在确保船舶交通更具可持续性。此外,到2050年,阿姆斯特丹港的目标是实现完全零排放的船舶交通。从2030年起,法律将要求邮轮使用船到岸供电。

"By installing a ship-to-shore power supply, we are working to improve air quality in the area and make cruises more sustainable," commented Dorine Bosman, Chief Investment Officer of the Port of Amsterdam. "We will also be more selective about which sea - going vessels are allowed to call. From 2024 onwards, older vessels (with older engines) will no longer be permitted to call at PTA. From 2025 onwards, ships that can connect to ship - to - shore power will be prioritized at PTA. We are investing in a clean port, clean vessel traffic, and a clean city."

“通过安装船到岸供电设施,我们正在努力改善该地区的空气质量,并使邮轮更具可持续性,”阿姆斯特丹港首席投资官Dorine Bosman评论道。“我们还将更加有选择性地允许哪些海上船只停靠。从2024年起,较旧的船只(使用较旧的发动机)将不再允许在PTA停靠。从2025年起,可以连接船到岸供电的船只将优先在PTA停靠。我们正在投资一个清洁的港口、清洁的船舶交通和一个清洁的城市。”

Port Overview

港口基本情况

As the port of Amsterdam, the Netherlands, this port was built in the 13th century and was an important port for the Dutch East India Company in the 17th century. Today, the Port of Amsterdam is the second - largest port in the Netherlands, after Rotterdam. Here are some basic facts about the port:

作为荷兰首都阿姆斯特丹的港口,这座港口建于13世纪,在17世纪时是荷兰东印度公司的一个重要港口。今天,阿姆斯特丹港是荷兰第二大港,仅次于鹿特丹港。以下是港口基本情况:

Geographical Location and Climatic Conditions

Amsterdam is located on the North Sea Canal in the western coastal region of the Netherlands, about 10 nautical miles from the canal's outlet at IJmuiden. Connected to the North Sea via the IJmuiden port lock, Amsterdam is the largest city and second - largest port in the Netherlands and also the world's first fully - equipped port.

The port has a temperate maritime climate, with prevailing westerly winds and mild, humid conditions. The annual average temperature ranges from a low of about 2°C to a high of about 19°C, and the annual precipitation is approximately 600 mm. Due to the separation by the ship lock, there is no tidal impact within the port.

地理位置与气候条件

阿姆斯特丹(AMSTERDAM)位于荷兰西部沿海的北海运河(NOORDZEE KANAAL)上,距运河出海口艾默伊登(IJMUIDEN)约10nm- ile。有艾默伊登港的船闸与北海沟通,是荷兰的最大城市和第二大海港,也是世界上第一可装卸大港。

该港属温带海洋性气候,盛行偏西风,温和潮湿。年平均气温最低约2℃,最高约19℃,全年平均降雨量约600mm。由于有船闸相隔,所以港内无潮差影响。

Dry Bulk Cargo Terminal

The dry bulk cargo terminal is equipped with high - speed portal cranes capable of lifting up to 50 tonnes, along with an automatic counting system. It also features two independent belt - conveyor systems, utilizing separate shore - based cranes capable of performing various operations such as transshipment and loading/unloading of trucks. The storage yard has a capacity of three million tonnes. Shipments from the storage yard can be loaded onto vessels at a rate of 2,000 tonnes per hour, while phosphate fertilizers can be unloaded at a daily rate of 7,000 tonnes. The grain terminal can accommodate vessels up to 100,000 deadweight tonnes, with a grain screening capacity of 800 tonnes per hour. The coal terminal is capable of handling coal, coke, fine coke, and coke dust. It is equipped with a 16 - ton floating crane and a 50 - ton grab unloader, providing loading/unloading services for ships, barges, and trains. It boasts optimal waterway, highway, and rail transportation links, enabling the swift and flexible transportation of coal in varying quantities, with a daily handling capacity reaching 40,000 tonnes.

干散货码头

干散货码头的高速门吊最大起重能力达50吨,并有自动计数系统;另有双套独立皮带联合输送机,使用分开的岸吊,可以同时进行过驳、装车等作业。堆场容量达300万吨,从堆场装船每小时为2000吨,磷肥每天可卸7000吨。谷物码头最大可靠10万载重吨的船舶,谷物筛选每小时可筛卸800吨。煤碳码头可装卸煤炭、焦炭、细焦炭和焦炭粉等,有16吨的浮式起重机和50吨的抓斗装卸桥,可为轮船、驳船和火车装卸,并且具有最佳的水路、公路和铁路运输线,能迅速、灵活地运输大小批量的煤炭,日装卸能力每天可达4万吨。

Container Terminal

The container terminal features container cranes with an outreach of 36 meters, equipped with spreaders adjustable up to 12 meters to handle two 20-foot containers simultaneously. Additionally, there are 45-ton rail-mounted container handling vehicles with a rotating outreach of 40 meters, fitted with rotating and adjustable spreaders capable of servicing three rail tracks. The oil terminal can accommodate oil tankers up to 100,000 deadweight tonnes and is equipped with pipelines of 152.4 to 203.2 millimeters in diameter, capable of loading/unloading crude oil at a rate of approximately 2,000 tonnes per hour. The port has established bonded warehouses to attract foreign businesses to choose the Netherlands as a distribution center for exports to Europe, Asia, Africa, and other regions. Goods entering this area are exempt from import duties. Commodities stored in the bonded warehouses can be used for simple packaging, sample exhibitions, trials, and component assembly.

集装箱码头

集装箱码头的集装箱吊外伸横距达36m,并附有12m距离的调节器(SPREADERS)可同时吊装2只20英尺的集装箱;还有45吨的铁道移动式集装箱吊运车、旋转跨距达40m,并装有回转幅度和可调节的伸张器,可为3条路轨服务。油码头最大可靠10万载重吨的油船,有直径为152.4~203.2mm的输油管,每小时装卸原油约2000吨。本港设立保税仓库是为了争取外商选择荷兰作为对欧、亚、非洲各国出口的分销中心。商品进入该区免交进口税,储存在仓库的商品可以进行简单包装,样品展览试验之用,也可作零件装配。

In this issue, we spotlight two vessel fire incidents spanning Europe and Asia. Both the Amsterdam Port electrical short-circuit and the sub-standard charging device on the Huangpu River point to the vulnerability of vessel electrical systems in harsh environments. Factors like humidity, salt fog, and vibration, combined with equipment aging and violations, can escalate minor electrical issues into catastrophic fires. Despite the IMO's technical standards, there's a significant gap between paper regulations and actual maritime practices. Going forward, it's crucial to prioritize vessel circuit safety through enhanced inspections, crew-operation standardization, and improved emergency - response systems. This will mitigate fire risks and ensure the safety and sustainable development of the shipping industry.

本期我们聚焦的这两起跨越欧亚的船舶火灾事故,无论是阿姆斯特丹港的电线短路,还是黄浦江上的劣质充电设备,都指向船舶电气系统在复杂环境下的脆弱性,潮湿、盐雾与震动的特殊环境,叠加设备老化与违规操作,足以让细微的电路隐患演变为灾难性火情。“小短路”背后面临“大风险”,尽管国际海事组织已通过技术规范搭建起安全框架,但纸上标准与海上实践之间仍横亘着执行鸿沟。未来,更加需要高度重视船舶电路安全,加强日常检查与维护,规范船员操作,完善应急响应机制,以降低火灾风险,保障航运业的安全与可持续发展。